|

The more you do it the easier it gets {unless you play football for England that is.....} That saying is definitely true when it comes to using a jeweller's saw. From really not enjoying cutting metal with a saw and using shears if it was at all possible, I now love using my saw and wielded it almost like a pro {almost} to cut out some cute shapes recently.

I'd downloaded a lot of shape silhouettes from a graphics site that had a 7 day free trial a couple of weeks ago and I chose a frame shape and a five petal flower shape to start with. I resized the shapes in Word then printed them out and stuck them onto the metal. The flower shape was a bit trickier that the frame shape but I got there eventually.

I domed the flowers and bezel set a London Blue topaz cabochon in the centre. It's the first time I've used the LB topaz and I must say it is a beautiful sky blue stone. Keeping with the blue theme I set turquoise and sodalite cabochons on the copper "frame" earrings and did another new thing which was to solder the hanging loops closed on the earwires on both pairs for added security.

Continuing with the shape theme I was asked recently if I could do a square version of my enamelled discs for a customer who had a necklace made from green enamel squares and wanted to make herself a pair of earrings to match.

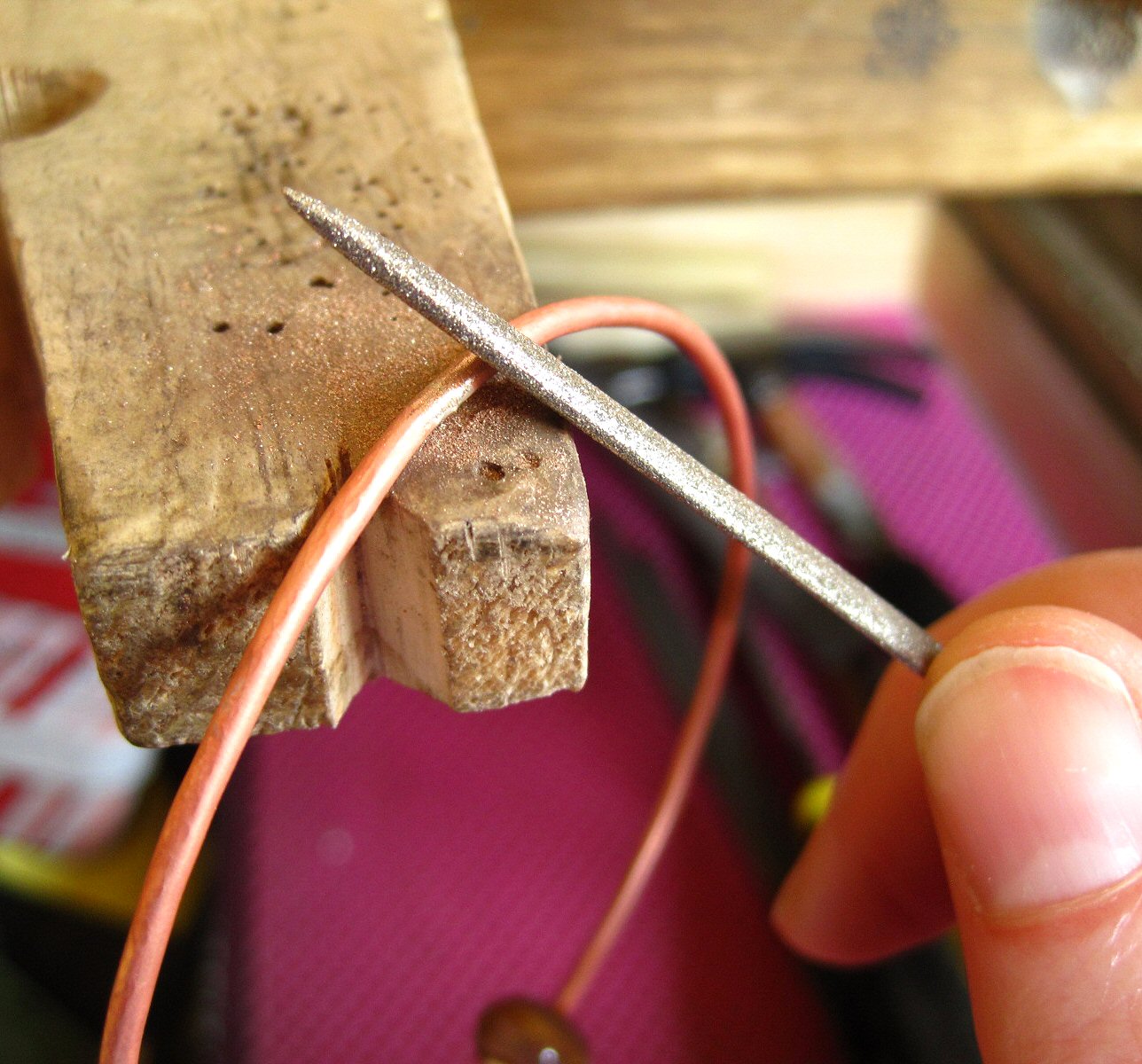

The copper squares cut and holes punched.

.

Counter enamelling done and the first two squares given their colourful enamel coats in lichen green

Finished! Mint, lichen and pea green :D

I have new colours! Thompson enamels from EnamelSupply in Denmark {not the speediest of service but faster than ordering from the US}

The new colours include opaques in willow green, mauve purple and bitter green which is a shade I've seen used and really liked but have only just gotten round to ordering and transparents in geranium pink and woodrow red which I'll need to wash if I want to use on top of an opaque. I also topped up with seafoam green which is a lovely colour and very popular.

I can feel an enamelling session coming on.......