Like most metalwork jewellery makers I've developed a love of the tools I use and quite enjoy a browse in any shop that sells hammers and that kind of thing to see if there's something I could use. I sometimes come home with small toolish "things" that I don't even know the name of but think they look promising for use in my shed....

One of the tools that caught my eye recently was a mitre jig. A mitre jig or jeweller's jig is a small three part piece of steel that does some pretty wonderous things in the way of making a jewellery maker's life a lot easier!

I've come across mitre jigs before {but only from a distance} and knew they were used to get straight edges and angles on things and that joiners used them but it all looked a bit complicated and technical and precise which isn't a word that always applies to how I do things. But after watching a very useful video by David Wilson via Cookson Gold on how to use a mitre jig I realized I really needed one. After seeing the price of them at Cooksons {about £55!} I looked elsewhere and bought one from Cousins UK for about £27. The only difference is the Cousin's mitre jig only has one set of knurled {good word!} nuts on the top where the Cookson's version also has one of them on either side of the jig.

Enough about knurled nuts.....so what can you do with a mitre jig? You can do lots of very useful things in the way of getting a straight edge on wire, tube and sheet. I make a lot of bangles and where I previously would file the ends straight {which in my world meant not really that straight} by bracing the wire against my bench peg and filing I now use the mitre jig...

I undo the nuts {knurled} and feed the end of the wire into the relevant sized slot on the bottom section of the jig. This is the part you use to achieve a flat, straight edge to your metal. Tighten up the nuts and you are ready to file. I rested the jig on my bench peg with the end of the wire hanging down between the V slot on the bench peg. I then held the jig with one hand and filed right to left with the other hand until the end was flush with the surface of the jig. It takes seconds and gives you nice clean straight edges making soldering and clean up easier.

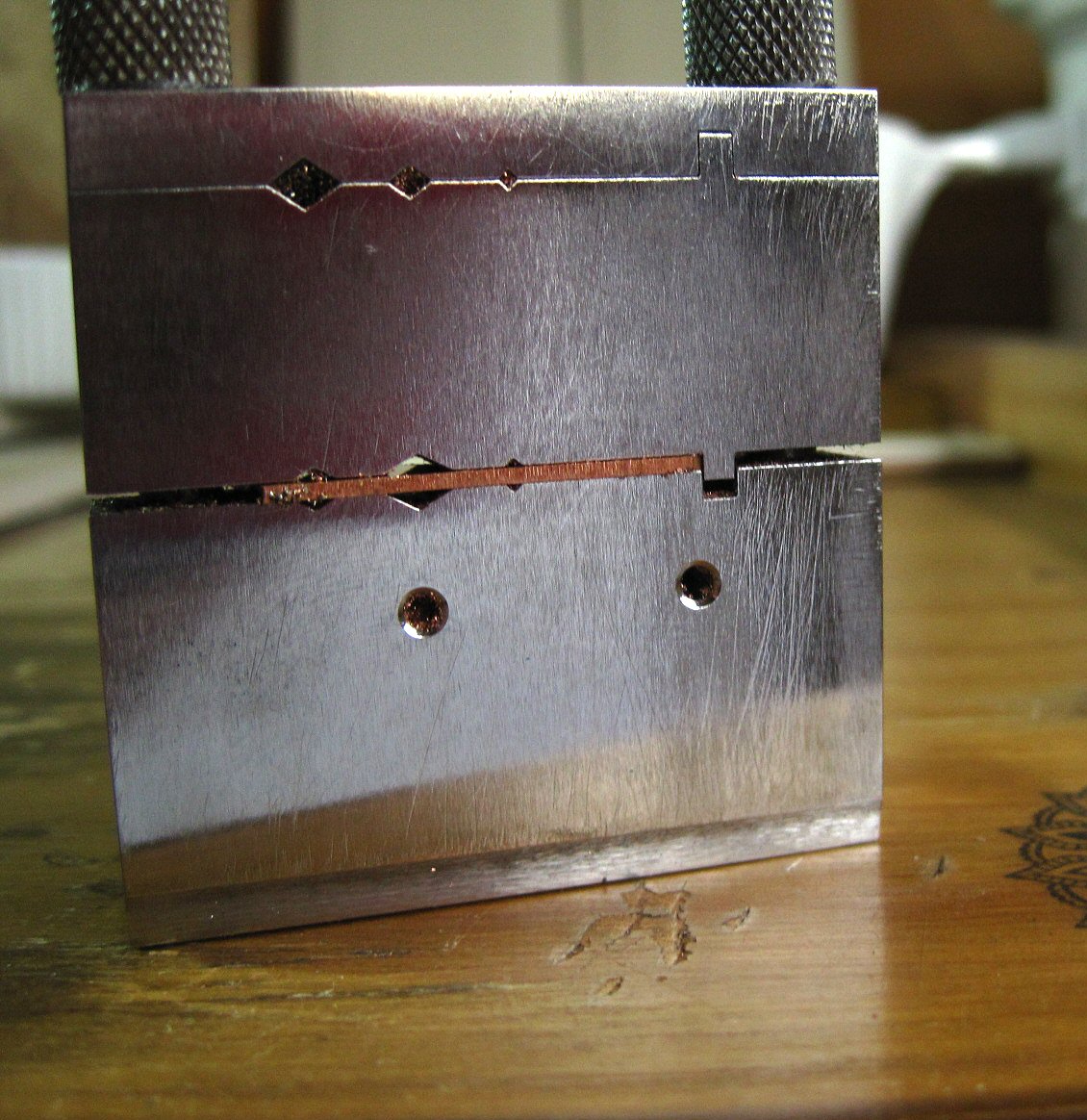

Filing the metal does produce a lip which you can see in this photo making the join look a bit wavy but you'll just have to believe me when I say there was no light between the ends when I held it up to the light and when it was soldered the solder jumped into the join with glee :D

Another good use for the jig is for filing a flat section on a ring band ready for soldering on a bezel. I usually brace against my bench peg to do this but as my bench peg isn't particularly level I normally end up with a flat area that tilts to one side so end up filing it several times before it's completely level.

Using the mitre jig as a vice you can then file off a section of the ring band quickly and it will be totally flat so no more messing about holding it up and squinting at it to see if it's level which is what I tended to do.

You can also use the mitre jig to file a straight edge on sheet metal. If you know you already have one true straight edge you simply butt the metal up to the square notch which will make sure it's at the correct 90 degree angle then you can start filing. You can also use it to straighten up the ends of bezel wire {very useful!}, rings bands, etc, etc, in fact anything that needs a straight edge.

You can also use your jeweller's saw with the mitre jig to remove excess metal or to cut tube if you don't have a tube cutter. It's so useful and I haven't even mentioned the top slot which does exactly the same as the bottom slot but at a 45 degree angle!

The video is worth watching but I was a bit puzzled at the part where he attaches the mitre jig to the piece of wood that can then be clamped into a vice. I couldn't work out how you would use it with the wood behind it as you wouldn't be able to feed the metal through from the back.....

I'm not affiliated with Cookson Gold or Cousins UK so this wasn't written to advertise their products..... I just wanted to share what a fab tool it was! And use the word knurled several times.